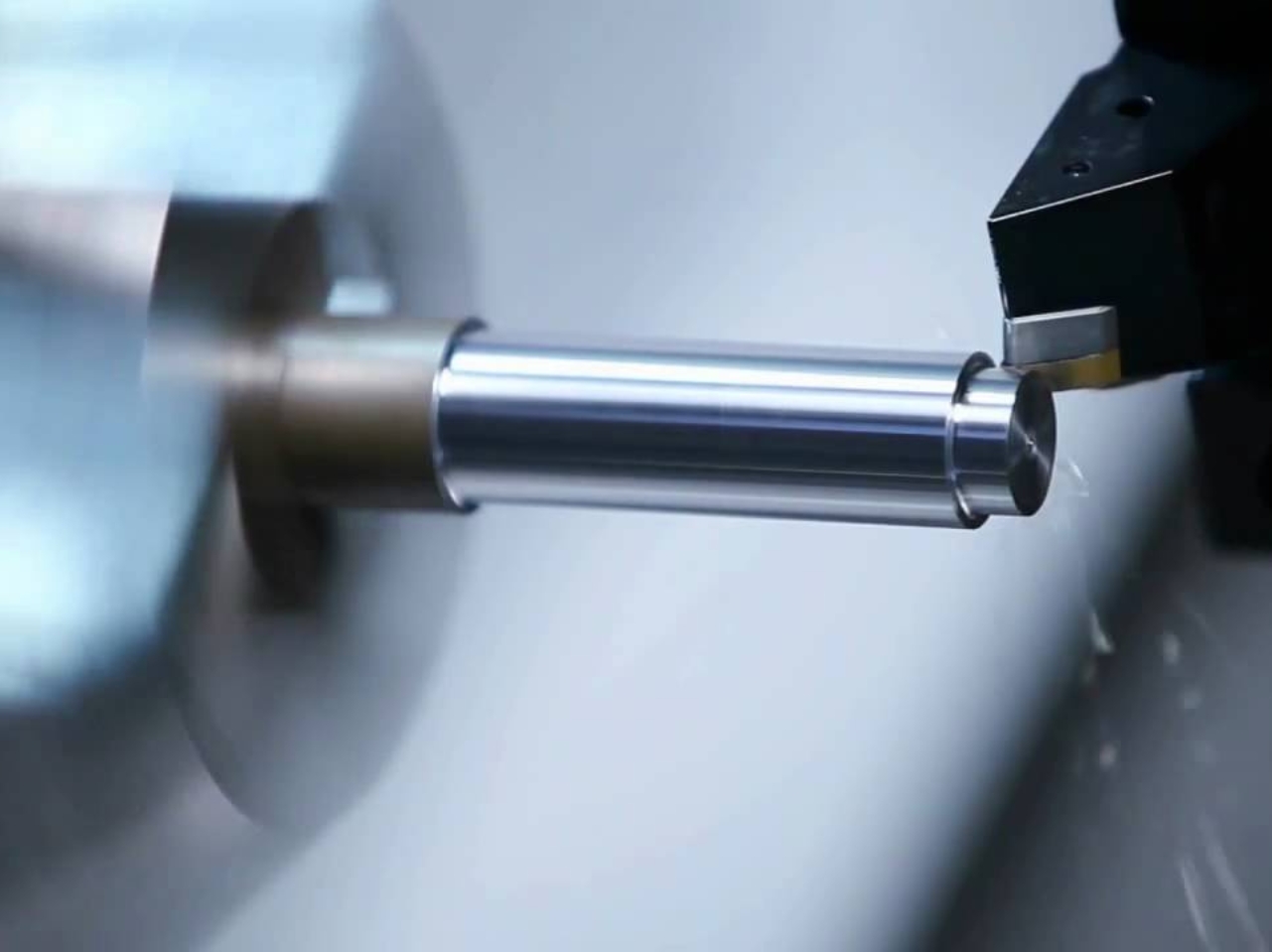

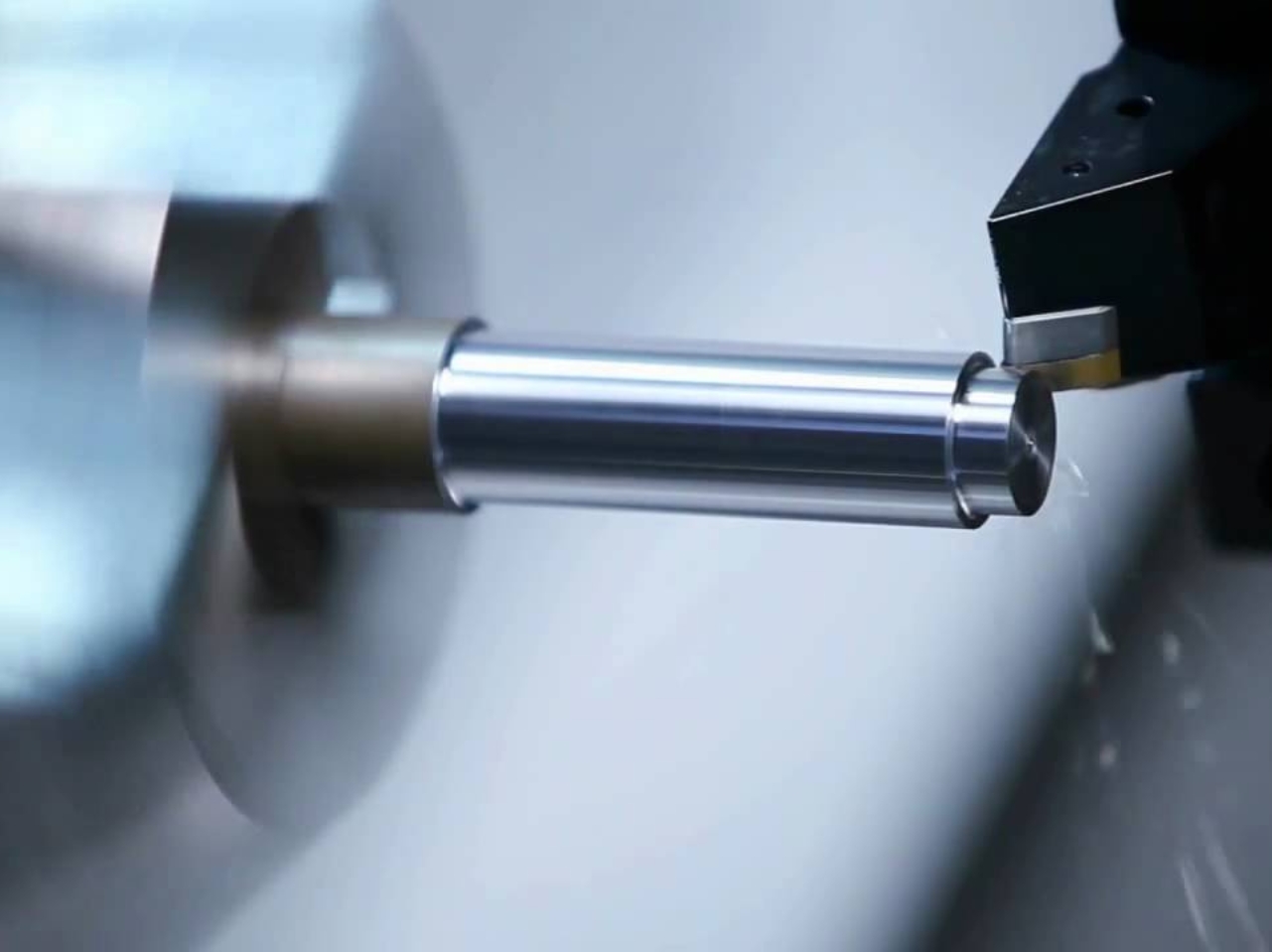

CNC Turning and CNC Machining are both advanced manufacturing processes that offer precision and efficiency, essential for producing high-quality components across various industries. CNC Turning involves rotating a workpiece while a fixed cutting tool shapes it, making it ideal for creating cylindrical or round parts with tight tolerances. This process is highly automated, reducing human error and ensuring consistent results, and is commonly used for producing components like shafts, pistons, and engine parts in industries such as aerospace, automotive, and medical. The ability to efficiently remove material and create complex geometries with minimal waste makes CNC turning an invaluable technique for high-performance applications.

On the other hand, CNC Machining encompasses a broader range of processes, including milling, drilling, and grinding, to create intricate and complex shapes from a variety of materials. CNC machining allows for more flexibility, enabling the production of detailed and precise components that may have non-cylindrical geometries. This versatility makes CNC machining suitable for industries such as aerospace, medical, electronics, and energy, where precision and reliability are crucial. While CNC turning is particularly efficient for cylindrical parts, CNC machining excels at handling a wide range of shapes and applications, offering speed and accuracy in creating detailed components with high precision. Together, these technologies play a key role in modern manufacturing, ensuring the production of durable, high-quality parts that meet rigorous standards.

Plot No 47, Buddha Chowk, near EK MURTI, Ecotech - 12, Greater Noida, Noida, Uttar Pradesh 201318

salesinfo.elegance@gmail.com

+91 70118 15711